Vacuum Metalizing Co. Inc.

Vacuum Metalizing Co. Inc.Request A Quote

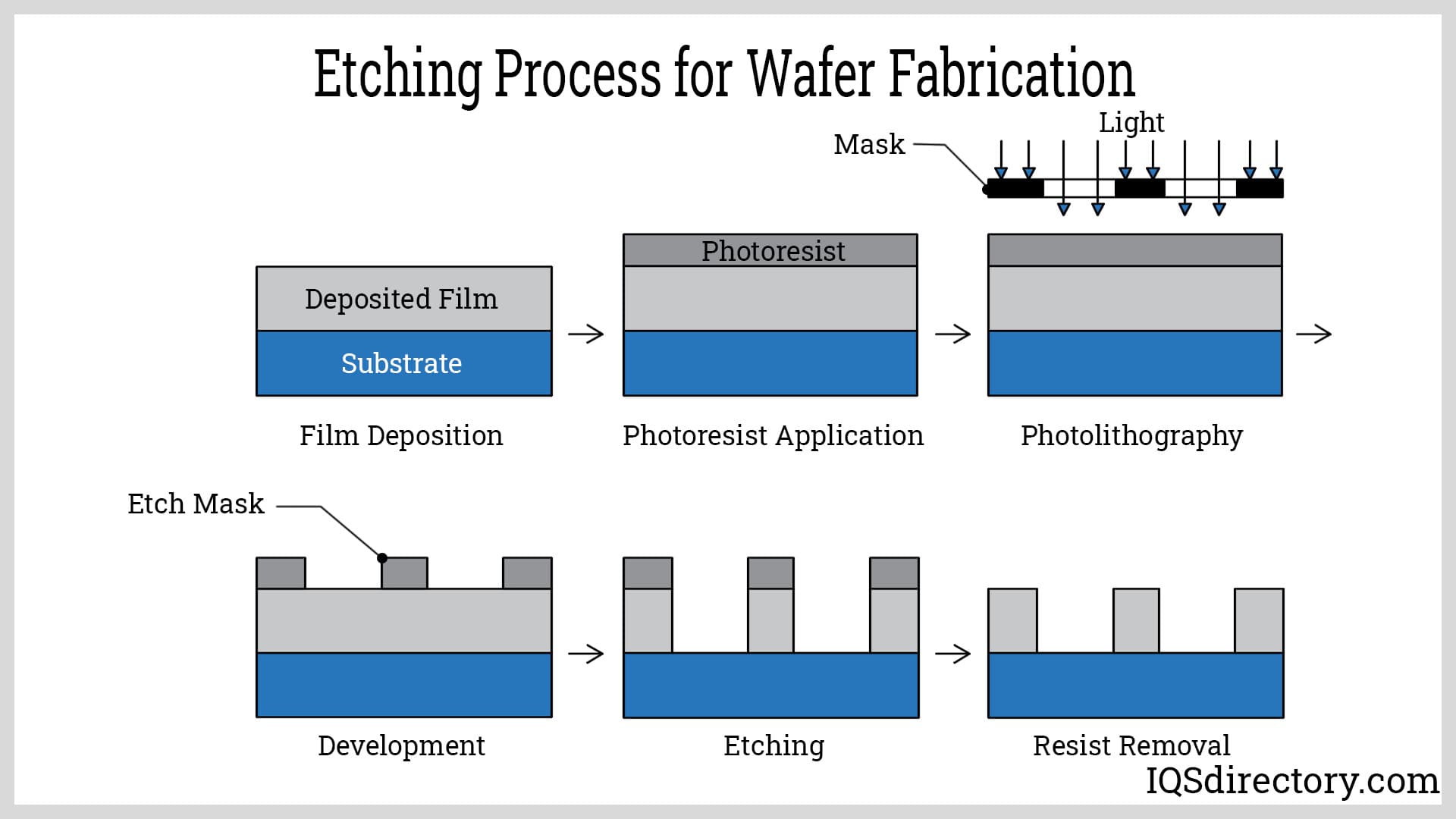

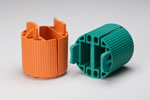

Rancho Cucamonga, CAVacuum metalizing is a process that involves the deposition of thin metallic coatings onto a substrate using a vacuum chamber. This technique is commonly used in various industries, including automotive, aerospace, and electronics, for its ability to provide functional and aesthetic benefits to a wide range of surfaces. One of the primary applications of vacuum metalizing is in the manufacturing of electromagnetic interference (EMI) shielding products, which are essential for preventing electromagnetic waves from interfering with electronic devices. EMI shielding is a critical requirement for electronic products that require high levels of reliability and performance. Electromagnetic interference can disrupt electronic signals, leading to malfunction or failure of the device. Vacuum metalizing offers a highly effective and cost-efficient solution for manufacturing EMI shielding products. The process involves depositing a thin layer of metal, such as aluminum or copper, onto the surface of the substrate. The metal coating creates a barrier that prevents electromagnetic waves from penetrating the surface, thus providing effective EMI shielding. Vacuum metalizing companies specializing in EMI shielding products have extensive capabilities to meet the complex requirements of their customers. These capabilities include design and engineering services, material selection and testing, prototyping, and large-scale production. With state-of-the-art equipment and highly skilled technicians, these companies can produce EMI shielding products of various shapes and sizes, from small electronic components to large industrial equipment. In addition to EMI shielding products, vacuum metalizing companies offer a wide range of other products and services. These include decorative coatings, reflective coatings, and barrier coatings for various industries, including automotive, consumer electronics, and aerospace. Vacuum metalizing is also an eco-friendly process that produces minimal waste and uses non-toxic materials, making it a popular choice for companies committed to sustainability. Overall, vacuum metalizing companies specializing in EMI shielding products offer a highly effective and cost-efficient solution for electronic manufacturers seeking reliable and high-performance EMI shielding. With their extensive capabilities and expertise in the vacuum metalizing process, these companies provide a critical service to various industries and play a crucial role in ensuring the reliability and performance of electronic devices.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

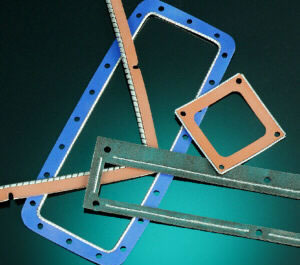

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services