RFI gaskets, also called EMI gaskets, function to preserve the continuity of flow into EMI/RFI shields and generally help reduce RFI (radio frequency interference). Without RFI gaskets, any gaps or slots in an EMI/RFI shield will allow radio frequency or electromagnetic fields to flow through the shield without proper regulation. Read More…

Spira Manufacturing Corp. offers the most reliable EMI gaskets & shielding for the electrical / electronic industries to meet required EMC/EMI shielding regulations.

Sealing Devices is a leading North American distributor and fabricator of EMI shielding products, including conductive elastomers, Soft-Shield® low closure force gasketing, windows, conductive adhesives, formed-in-place parts, vents and elastomers.

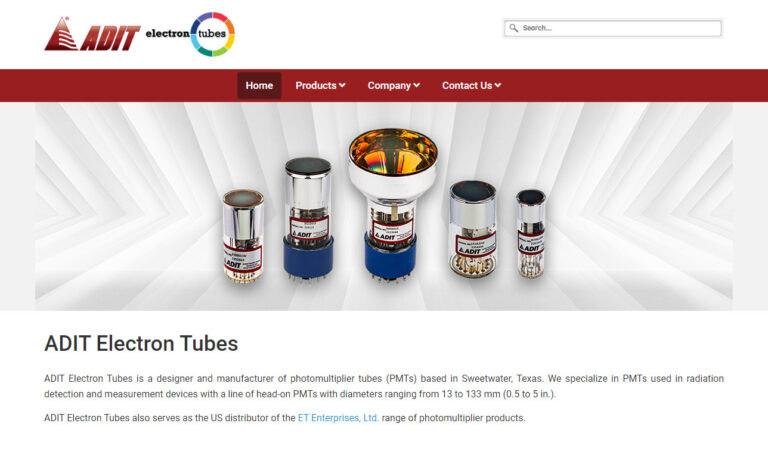

We are one of the first in EMI technologies! Our roots trace back as early as the 1930s. We work hard to bring you the latest and greatest in EMI technologies and distribution. ADIT Electron Tubes manufactures low-level light detection systems and devices. Our photomultipliers are apart of a major international industry that we are a supplier of. Call us today for more information about our EMI...

FMS has been eliminating electromagnetic interference (EMI) and radio frequency interference (RFI) issues in commercial & industrial buildings, medical facilities, and research laboratories for over 25 years. Using the latest technology, backed by independent research and development, FMS delivers customized, innovative mitigation solutions for the most complex interference problems worldwide.

More RFI Gasket Companies

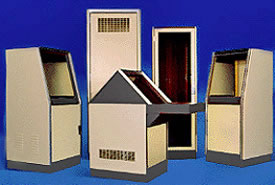

RFI gaskets serve many industries and general applications, such as aerospace, automotive electronics, computers, data communications, general electronics, medical equipment, military, network equipment and telecommunications.

The ideal surface of an RFI gasket is rigid and recessed to completely house the gasket and be as conductive as possible. Gaskets are available in many shapes, sizes and materials. Additionally, many RFI gaskets are available for specific applications, making a buyer's choices nearly endless.

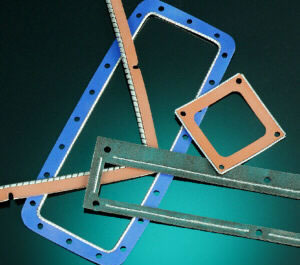

Materials that are used in gasket fabrication include, but are not limited to: knitted mesh (metal wire), FUBA foam, polyurethane foam (coated with an alloy or alloys for conductivity), electrically conductive rubber, beryllium-copper, alloy coated rubber and metalized fabric.

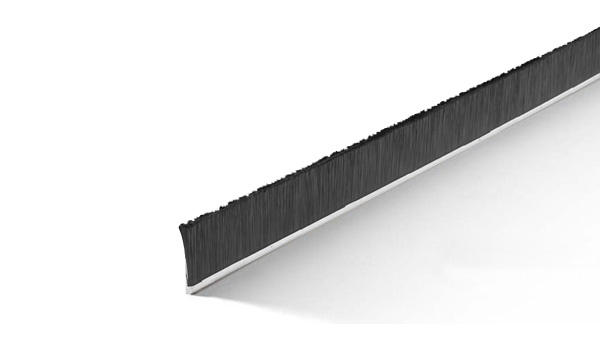

Examples of shapes or forms in which RFI gaskets may manifest include: fingerstrips, miniature shields, standard and irregularly-shaped flexible clip on gaskets, O-profile, frame, V-shaped, P-shaped and U-shaped gaskets and custom gaskets. Other gasket types include: oriented wire shield, EMC/IP, die-cut, ultra-soft shield, ultra-soft twin shield, metal clip on gaskets and connector gaskets.

To determine the characteristics and materials of your RFI gaskets, consider your application and requirements. Ask yourself: Does my application require a gasket that ensures, in addition to electrical conductivity, a good water seal? Should the gasket I buy be so soft that the lid or door that is closed on it does not become bent or scraped? What is my desired attenuation?

Different gasket materials and heat sensitivities offer different attributes, like the following: low-frequency magnetic shielding, extreme condition/environment suitability, wear resistance, corrosion resistance, temperature resistance, easy application and low-closure force. Gaskets can be customized with coatings, such as polymer resin or nickel, for your specific needs.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services