EMF radiation is the emission that some electronic equipment emits. EMF protection systems shield vulnerable objects and persons from the dangers that various types of electronic gadgets’ electromotive forces may pose. EMF protection needs magnetic filtering materials or products to prevent electromagnetic fields (EMF) from interacting with delicate devices and human touch. Read More…

Spira Manufacturing Corp. offers the most reliable EMI gaskets & shielding for the electrical / electronic industries to meet required EMC/EMI shielding regulations.

Sealing Devices is a leading North American distributor and fabricator of EMI shielding products, including conductive elastomers, Soft-Shield® low closure force gasketing, windows, conductive adhesives, formed-in-place parts, vents and elastomers.

We are one of the first in EMI technologies! Our roots trace back as early as the 1930s. We work hard to bring you the latest and greatest in EMI technologies and distribution. ADIT Electron Tubes manufactures low-level light detection systems and devices. Our photomultipliers are apart of a major international industry that we are a supplier of. Call us today for more information about our EMI...

FMS has been eliminating electromagnetic interference (EMI) and radio frequency interference (RFI) issues in commercial & industrial buildings, medical facilities, and research laboratories for over 25 years. Using the latest technology, backed by independent research and development, FMS delivers customized, innovative mitigation solutions for the most complex interference problems worldwide.

More EMF Protection Companies

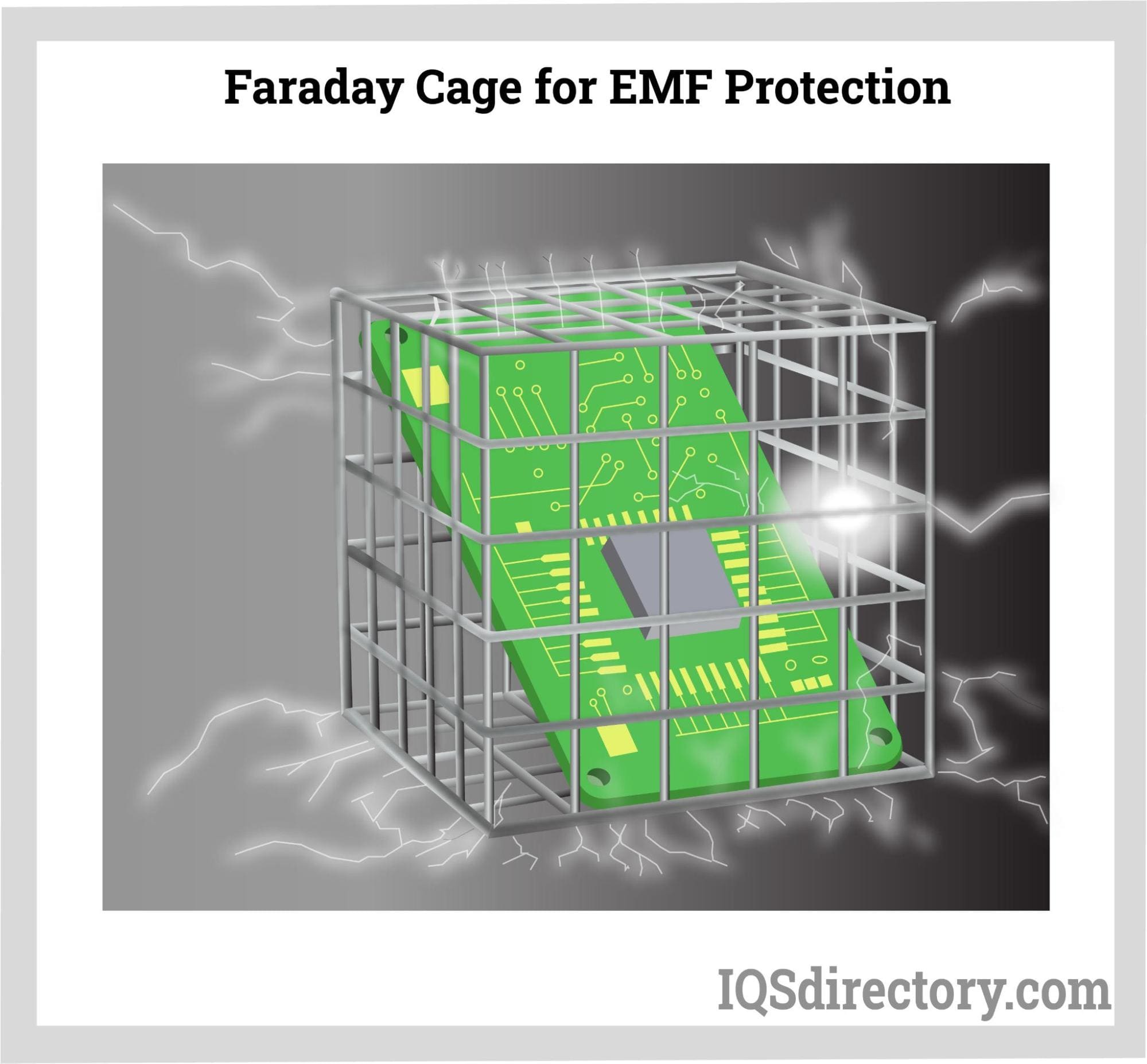

EMF is the term used to describe electromagnetic fields that vibrate at frequencies ranging from nearly zero to billions of times each second and even faster. Ionizing radiation is produced by higher frequencies, whereas the lower frequencies produce non-ionizing radiation. As a result, low - frequencies are more likely to harm people's health than high frequencies, which are more likely to cause issues and interfere with sensitive equipment.

Communication equipment like wireless Internet, cell phones, televisions, baby monitors, security systems, radios, and computers are a few sensitive gadgets that may need EMF protection at high frequencies. Particularly vulnerable are wireless communication devices. In addition, childhood leukemia, chronic pain, adult cancer, exhaustion, nausea, and headaches are a few health issues linked to exposure to low-frequency EMFs.

The two different EMF frequency levels behave differently. High-frequency electromagnetic fields (EMF) operate similarly to light beams in that they do not bend but rather reflect off objects. Electric and magnetic fields combine to generate electromagnetic fields at these frequencies, typically above 300 kHz. Low-frequency EMF behaves very differently. Below 300 kHz, the electric and magnetic fields are distinct at these frequencies. These frequencies act much more like actual sound waves than light beams. In other words, similar to sound waves, these frequencies will swell and contract when reflected.

Applications of EMF Protection

In an industrial setup, anywhere can let radiation be exposed to workers. For this reason, a lot of consumers and industry workers can stay safe from radiation risks because of the protection offered by EMF shielding materials. These goods include garments, wall insulation, blankets, water filters, mats, coatings, and a wide range of other things. The negative effects of EMF can be avoided using a variety of techniques.

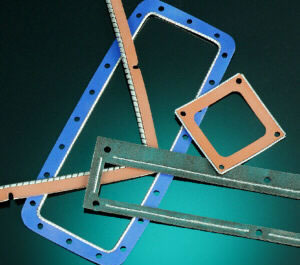

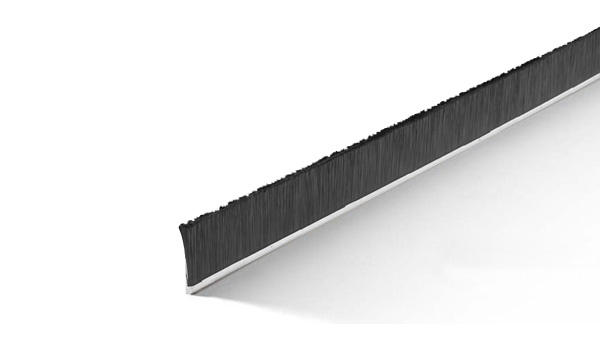

Products used frequently to defend against EMFs include shields, gaskets, filters, and enclosures. Mu metal, 15% iron, 77% nickel, and a small proportion of copper and molybdenum nickel-iron alloy are among the most popular materials used to create EMF protection equipment. Sendut, molybdenum permalloy, Hipernom™, epoxy resin, polyurethane foam, and supermalloy are substitute materials that can also be used for EMF protection.

EMF radiation's negative impacts are minimal. However, the impacts of EMF exposure include symptoms such as hormone imbalances, exhaustion, and headaches. Therefore, most factories should ensure that EMF and EMI shielding is current and functioning properly to protect workers.

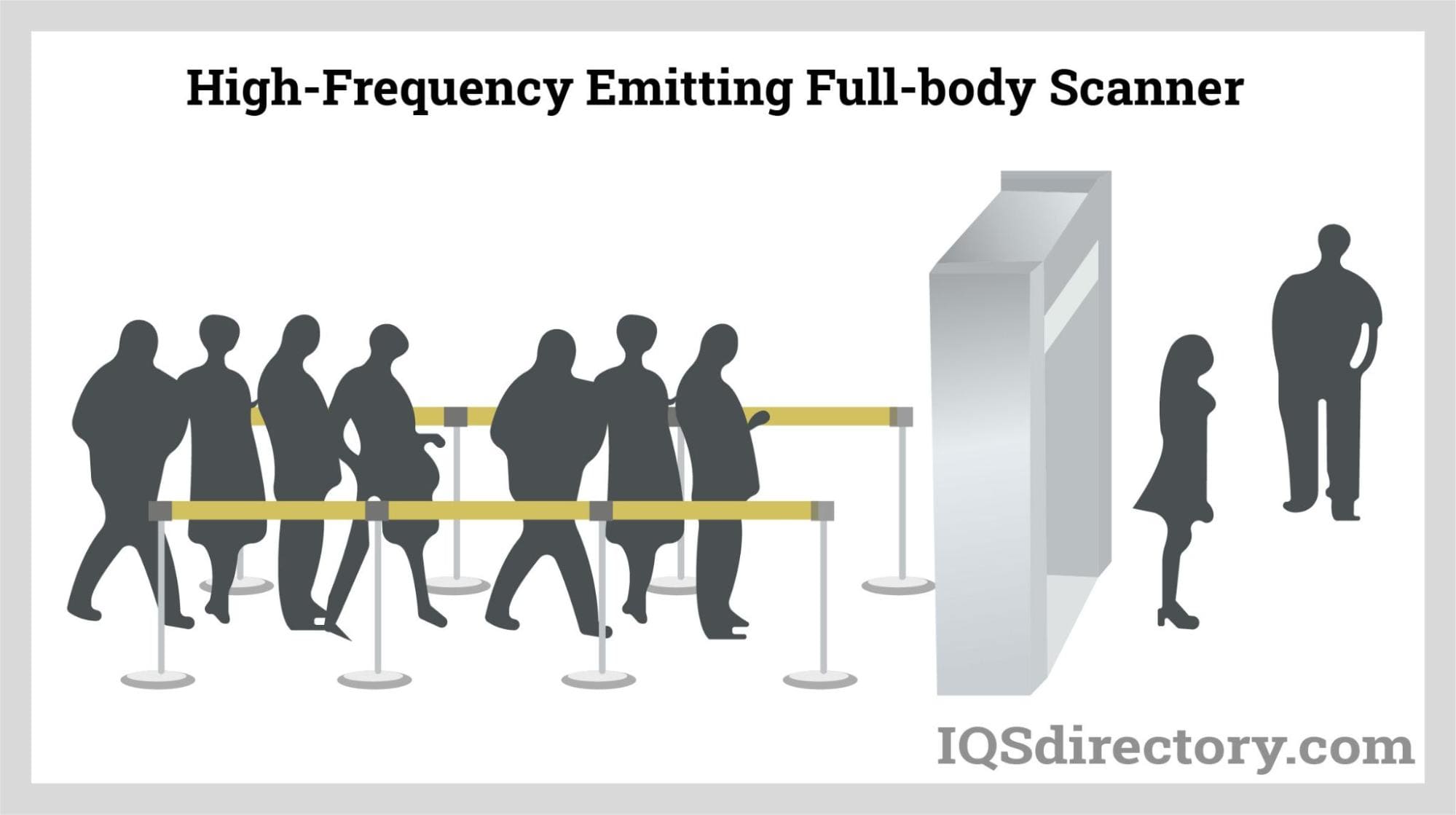

High-Frequency Fields

The portion of the electromagnetic spectrum containing frequencies between 100 kHz and 300 GHz is covered by high-frequency electromagnetic fields. The high-frequency electromagnetic fields are dispersed through an antenna. They can transmit information and energy over enormous distances.

Many emitting facilities operate at different transmitting powers and frequencies because high-frequency electromagnetic fields are used for many applications, including radio and cordless phones, mobile communication, wireless LAN, Bluetooth® connections, and TV broadcasts.

EMF shielding is necessary where there are occupied areas to reduce the occupant exposure to 50 Hz EMF fields associated with the high current carrying cables and transformers. The areas include offices, apartments, retail spaces close to or above substations, switch rooms, or high-current power cabling.

EMF Protection for High Frequency

A magnetic shielding plate blocks any magnetic field, whether alternating or static, which is ideal for shielding broad surface areas.

Low-Frequency Fields

This kind of radiation is non-ionizing. This radiation is emitted by common household items, including microwave ovens, smartphones, hair dryers, and washing machines, as well as by power lines and MRI machines. Extremely low-frequency and radiofrequency EMFs are included in this EMF group (RF-EMFs). Both natural and artificial processes can produce non-ionizing EMFs. There are two forms of human-made EMFs, both produced by non-ionizing radiation.

- Extremely low-frequency EMFs (ELF-EMFs). Several things, including power lines, electrical cabling, and home equipment like hair dryers, electric shavers, and blankets, can produce this non-ionizing radiation field.

- Radiofrequency radiation. Wireless gadgets, including mobile phones, smart meters, tablets, and laptop computers, create this non-ionizing radiation field. Additionally, radar, MRI equipment, satellite stations, and radio and television broadcasts produce it.

EMF Protection for Low Frequency

In homes, conductive paint is used on the interior walls to protect the occupants. The coatings can be painted over with water-based paint for the desired aesthetic after being applied straight to the walls without primer. Unfortunately, wireless devices like cell phones or computers linked via Wi-Fi will not function in some locations which are painted, limiting usage to just hardwired devices.

Magnetic forces are absorbed and diverted from the zone of concern when they come into contact with the M36 shield. These installations have four layers of M36 shield for EMF protection material. The sheets must cover every surface between substations, control rooms, and occupied areas, extending an additional 1 m around the next wall.

Choosing the Proper EMF Protection Supplier

To ensure you receive the most productive outcome when purchasing EMF protection from an EMF protection supplier, it is important to compare several companies using our directory of EMF protection suppliers. Each EMF protection supplier has a business profile page illustrating their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each EMF shielding business website using our proprietary website previewer to learn more about what each company specializes in. Then use our simple RFQ form to contact multiple EMF protection businesses with the same form.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services