These waves commonly affect AM/FM radios, cell phones and televisions. Because these electromagnetic waves can disrupt the function of many electronic devices, some kind of shielding needs to be integrated into the assembly of the device. Read More…

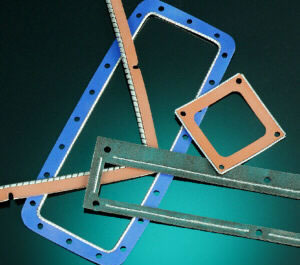

Spira Manufacturing Corp. offers the most reliable EMI gaskets & shielding for the electrical / electronic industries to meet required EMC/EMI shielding regulations.

Sealing Devices is a leading North American distributor and fabricator of EMI shielding products, including conductive elastomers, Soft-Shield® low closure force gasketing, windows, conductive adhesives, formed-in-place parts, vents and elastomers.

We are one of the first in EMI technologies! Our roots trace back as early as the 1930s. We work hard to bring you the latest and greatest in EMI technologies and distribution. ADIT Electron Tubes manufactures low-level light detection systems and devices. Our photomultipliers are apart of a major international industry that we are a supplier of. Call us today for more information about our EMI...

FMS has been eliminating electromagnetic interference (EMI) and radio frequency interference (RFI) issues in commercial & industrial buildings, medical facilities, and research laboratories for over 25 years. Using the latest technology, backed by independent research and development, FMS delivers customized, innovative mitigation solutions for the most complex interference problems worldwide.

More Magnetic Shielding Foil Companies

This is done using a variety of methods depending on the application. Mobile phones usually use a Faraday cage, a shield made of conductive metal that forms a small cage in which the components of the device are encased. Other pieces of equipment use a shield that is made of layers magnetic alloys that are highly permeable so that they absorb the electromagnetic waves instead of transferring them to the device that they protect.

More recent technological advances have allowed for a shielding method where a special spray with copper, nickel and aluminum particles is coated on to the plastic housing of a device.

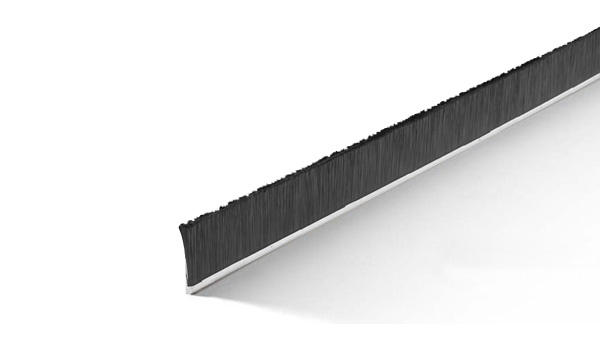

For applications where space is limited, a special type of magnetic shielding foil is used. This foil is available in a variety of sizes and permeability levels to meet the needs of the equipment with which it will be used.

Some manufacturers supply rolls of this foil to other product developers, and they will even produce custom sizes for large business clients. Magnetic shielding foil is used in sensitive electronic equipment like industrial controls, circuit control boards and more.

Because the foil is so thin, it can easily be cut and installed in tight spaces where there is not much room for heavy layers of protection. Shielding foil is also usually much cheaper than other shielding solutions.

The drawback of magnetic shielding foil is that it can usually only be used in low-intensity settings because the thin layer of foil does not allow for a great amount of electromagnetic absorption like a layer shield of Faraday cage would.

It is very easy to handle and install, and it can even be wrapped in spirals around a cable to prevent the wire inside from being disrupted by external electromagnetic waves or from emitting harmful signals beyond the cable.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

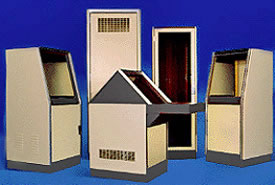

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services