Tech-Etch, Inc.

Tech-Etch, Inc.Request A Quote

Plymouth, MAIn 1964, Tech-Etch began as a small engraving company, through growth and innovation we grew into the metal etching company we are today. From our three manufacturing facilities, we distribute our thin metal parts, flexible printed circuits, and EMI/RFI shielding products worldwide. Our products are produced using a wide variety of manufacturing methods including photochemical etching and chemical plating. Through the dedication and skills of our employees we have our success. In 1999, we became an employee owned company by way of an Employee Stock Ownership Plan (ESOP).

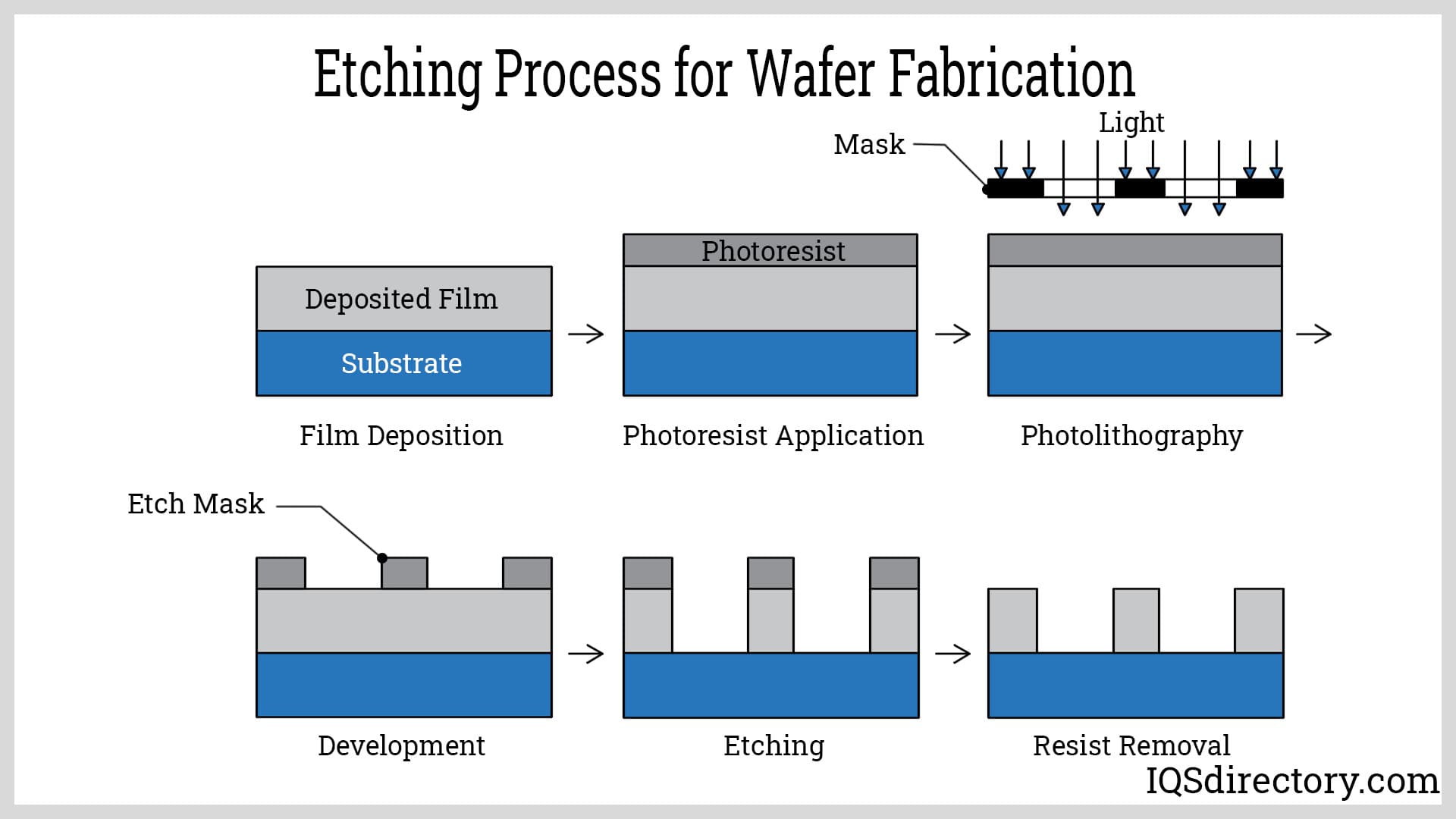

Our first class in-plant services include photoetching, stamping from coil stock and forming from etched blanks, tool and die making, production heat treating, flexible circuit design and production, welding, metal finishing, plating, and laser cutting. We specialize in light gauge metal parts from .0005" thick and up. The photo chemical etching process allows us to fabricate intricate metal components with tight, precise tolerances. Our processes reduce cost, improve design flexibility, and shorten lead times. We also have laser machining capabilities for thicker materials as well. By combining laser cutting with etching and forming, we are able to create thick parts with grooves or pockets.

We serve a variety of industries including but not limited to medical, aerospace, military, automotive, electronic, mechanical, and telecommunications. We put a focus on our customers' needs and you can count on us to only provide you with the very best. Tech-Etch is a dependable manufacturer and we can assist you by providing a fully customized solution. We perform a myriad of services in house so we can ensure you receive top of the line quality. Secondary operations we offer include soldering joints to seal seams, spot welding, and the application of pressure sensitive tapes and insulation materials. For reliable precision components and parts, turn to Tech-Etch.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

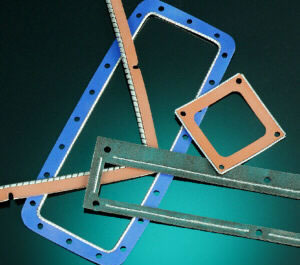

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services