Shielding sensitive electronic equipment from electromagnetic interference (and shielding high EMI-emitting equipment from contaminating other equipment) can be achieved by blocking the EMI with a conductive by coating equipment or equipment enclosures with EMI coating. Read More…

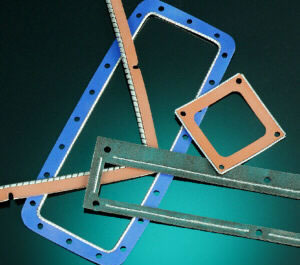

Spira Manufacturing Corp. offers the most reliable EMI gaskets & shielding for the electrical / electronic industries to meet required EMC/EMI shielding regulations.

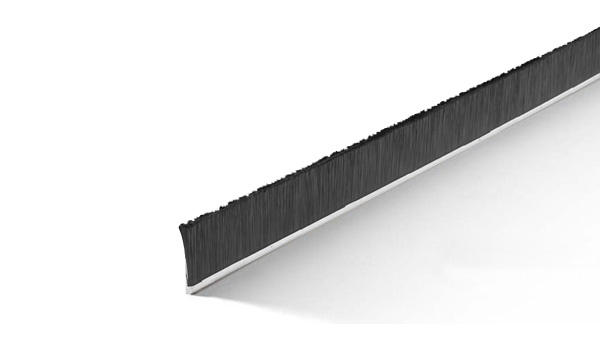

Sealing Devices is a leading North American distributor and fabricator of EMI shielding products, including conductive elastomers, Soft-Shield® low closure force gasketing, windows, conductive adhesives, formed-in-place parts, vents and elastomers.

Artcraft is a third-generation company founded in 1951. We offer a wide variety of services, including EMI and RFI shielding. From missile parts for the US military, to plating tubes for satellites launched into outer space, no project is too difficult for our team to handle. Call us today and tell us about your next project!

We are one of the first in EMI technologies! Our roots trace back as early as the 1930s. We work hard to bring you the latest and greatest in EMI technologies and distribution. ADIT Electron Tubes manufactures low-level light detection systems and devices. Our photomultipliers are apart of a major international industry that we are a supplier of. Call us today for more information about our EMI...

FMS has been eliminating electromagnetic interference (EMI) and radio frequency interference (RFI) issues in commercial & industrial buildings, medical facilities, and research laboratories for over 25 years. Using the latest technology, backed by independent research and development, FMS delivers customized, innovative mitigation solutions for the most complex interference problems worldwide.

More EMI Coating Companies

EMI coating allows for more flexible applications than EMI enclosures, as it may be spray-coated to any number of enclosures, areas and insulators.

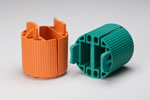

Various types of EMI coatings are often spray coated to the inside of plastic enclosures, surrounding the equipment which needs to be shielded in order to absorb harmful EMI and RFI. "Metal inks" containing copper, nickel or chromium alloys are EMI coatings which may be sprayed on to virtually any housing or material to create the effect of EMI shielding.

Electronic equipment manufacturers and suppliers use EMI enclosures in applications such as circuit board housings, central processing units, laptops and mobile phone housings. With circuit boards, CPUs, laptops and similar devices, most problematic EMI comes from electromagnetic cross-talk within the device.

Different components on the same board cause EMI to travel across wires and conductive materials, interfering with one another. EMI coatings may be sprayed onto wire insulation, circuit boards and onto the interior of small enclosures of integrated circuits, diminishing electromagnetic "cross-talk" within devices.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services